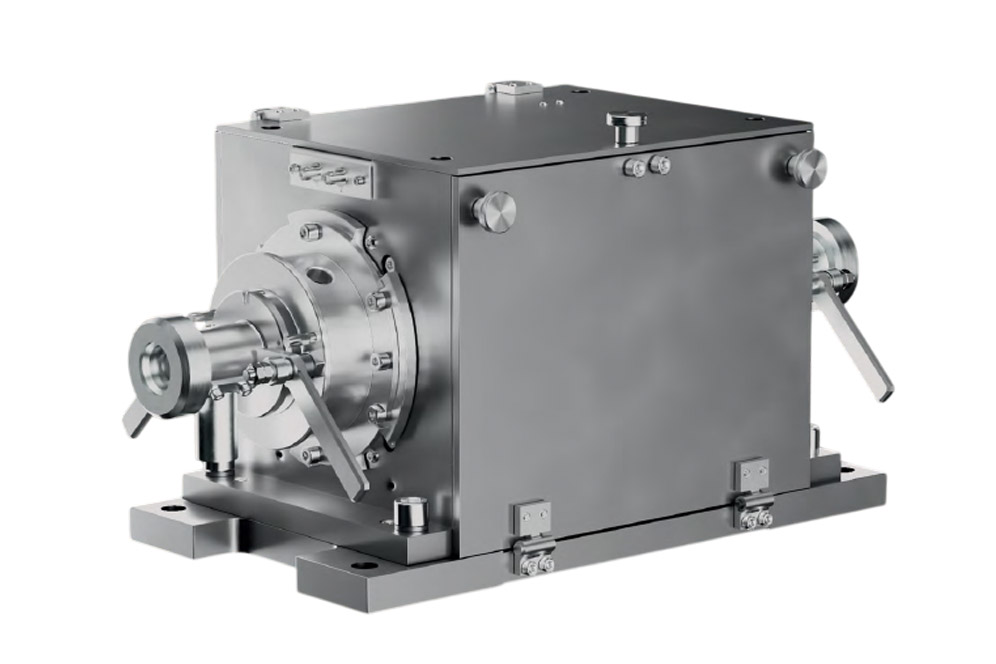

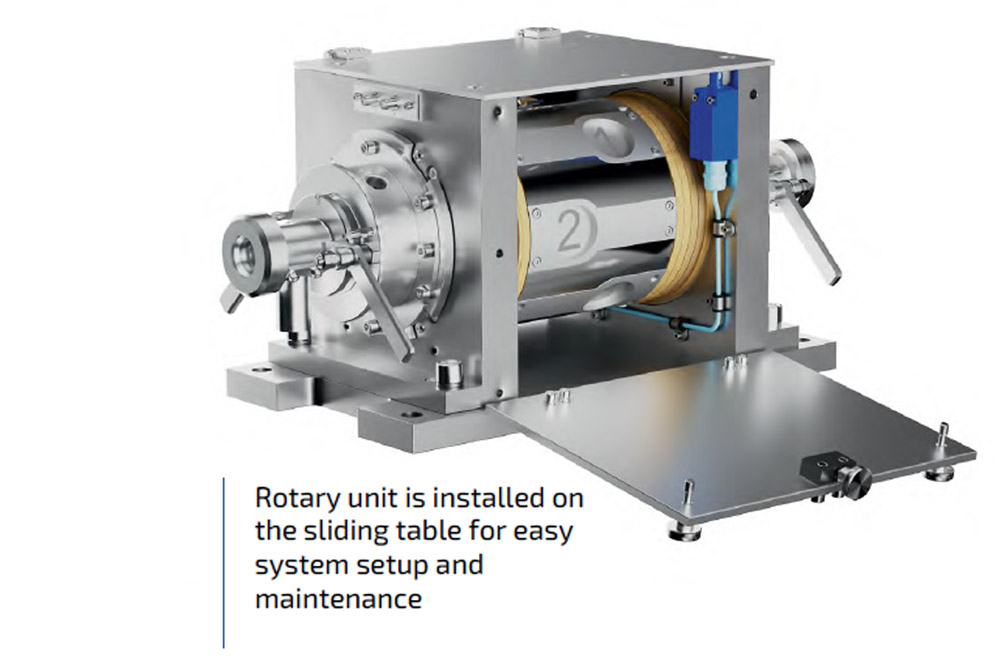

Automated Ut System Rotary Type for pipe and bar inspection

We manufacture Automated Ut System Rotary Type through

our sister concern, Pruftech.

HIGH-SPEED ULTRASONIC INSPECTION

PIPE DIAMETER FROM 4 TO 180 mm

UT ULTRA SONIC TESTING

Ultrasonic Testing (UT) is an NDT method that uses high-frequency sound waves to detect internal and surface defects in materials.

Principle of UT

- A probe (transducer) sends ultrasonic sound waves into the material.

- When the sound waves encounter:

- Cracks

- Voids

- Inclusions

- Back wall

- The sound waves are reflected back to the probe.

- These reflected echoes are displayed on the UT machine screen.

UT Applications

- Weld inspection

- Forgings & castings

- Pressure vessels

- Pipes & plates

- Thickness measurement

Advantages of UT

- Detects internal defects

- Deep penetration

- Immediate results

- Accurate sizing of flaws

Major Users of UT

- Oil & Gas Industry (Top User of UT)

- Power Generation Industry (Thermal, Nuclear, Hydro & Renewable Power Plants)

- Aerospace & Aviation Industry

- Manufacturing & Fabrication Industry

- Automotive Industry

- Construction & Infrastructure

- Shipbuilding & Marine Industry

- Railway Industry

- Steel & Metal Industry

- Defence & Military Industry

Versatility

Available in both manual and semi-automatic models to suit various testing needs.

High Capacity

Head shot and coil shot capabilities ranging from 1500 Amp to 10000 Amp.

Comprehensive Service

We offer installation services to ensure seamless setup and operation.